A recent study by McKinsey Global Institute has found that RPA can automate a whopping 70% of manufacturing activities. This statistic indicates the vast potential of a revolutionary RPA technology. Also known as Robotic Process Automation, RPA technology involves in developing and deploying software robots to automate mundane and rule-based tasks across different industry sectors. These software bots can tirelessly and flawlessly work on a 24×7 basis. In this post, we will dive into the impact and benefits of RPA in manufacturing industry. We will also discuss the transformative role of RPA along with some use cases.

Let's start with the key benefits of RPA in manufacturing.

Top Business Benefits of RPA in Manufacturing

The advantages of RPA in manufacturing go beyond automation. We can consider RPA as a game-changer for a thriving manufacturing industry as it can drive growth by offering multiple benefits including-

1. Increased Efficiency

Tireless RPA bots handle repetitive tasks like data entry, order processing, and report generation effectively. It can make workers free from such mundane activities and enable them to focus on problem-solving and quality control. It can boost efficiency and productivity in the manufacturing sector. Thanks to RPA, a major automotive manufacturer slashed order processing time from a sluggish 8 hours to a lightning-fast 1 minute.

2. Reduced Costs

RPA can reduce operational expenses with its laser focus on streamlining processes. By automating manual tasks, RPA reduces labor costs, eliminates human errors, and optimizes resource allocation by automating rule-based manual tasks. Interestingly, one aerospace giant estimated annual RPA-driven cost savings of a staggering $12 million! RPA consulting services can give you more ways through which this technology can save you money.

3. Reduced Errors

As an advanced technology, RPA brings accuracy to eliminate the chances of mistakes related to data entry and other repetitive tasks. These digital assistants ensure impeccable quality control. This leads to fewer defective products, happier customers, and a loyal customer base. A Deloitte study has found that RPA implementation led to a 99.7% reduction in invoice processing errors in a manufacturing company.

4. Higher Transparency

RPA focuses on transparency by automating data capture and reporting. It ensures both traceability and compliance with regulations. A healthcare giant Johnson & Johnson uses RPA to ensure meticulous compliance with strict medical regulations. Such increased transparency can help the manufacturing sector grow in the right direction and at a proper pace. As a manufacturer, you can get an edge over peers by following all the prevalent regulations.

Here we have mentioned several benefits of RPA in the manufacturing sector. Let's dive deeper into RPA use cases in the manufacturing industry to understand its impact in bringing transformative changes.

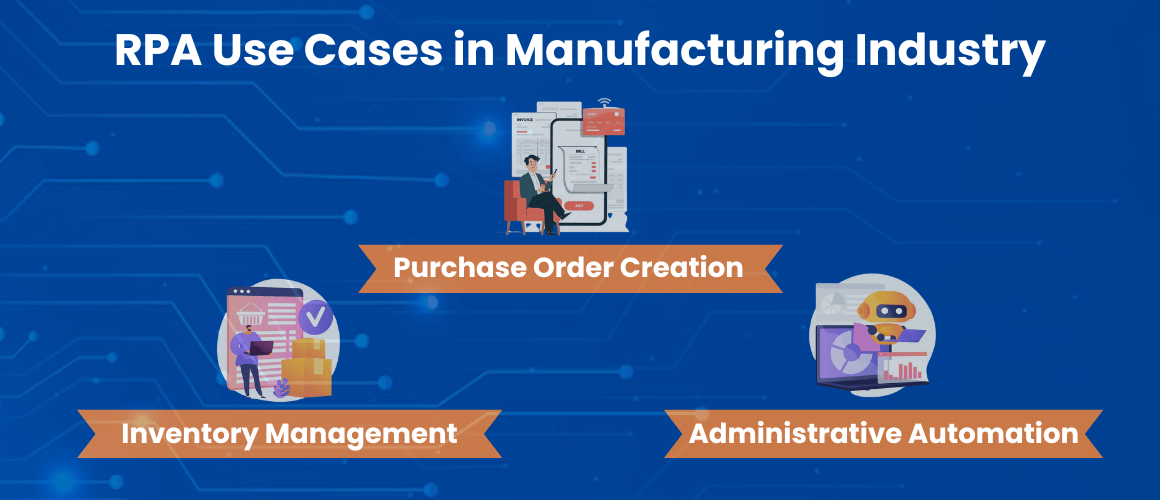

RPA Use Cases in Manufacturing Industry

This emerging technology has written many success stories in the manufacturing industry. We will go through several such use cases.

- Inventory Management

Be it stock auditing or asset tracking, inventory management has a crucial role in any manufacturing company. However, many manufacturing industries have involved a tremendous amount of paperwork in managing inventory. RPA in manufacturing can automate this process by giving real-time information to inventory managers. It can improve stock monitoring and enable managers to make informed decisions.

- Purchase Order Creation

It is a daunting manual process especially if your manufacturing company deals with multiple products across different categories. The staff must generate hundreds of thousands of purchase orders regularly for multiple vendors. Here, RPA can automate the entire process of creating purchase orders. Bots can pull out data from the business system and seek email approval from relative departments before sending purchase orders.

- Administrative Automation

Administrative tasks are highly time-consuming and arduous. If your employees can be set free from such tasks, they can focus more on other important activities. RPA in manufacturing industry is designed to achieve this objective. It can automate the recording and documentation of meeting minutes, daily attendance, email answering, and scheduling meetings. Your employees can get reminders for meetings and completed invoices for approval using the RPA.

However, the implementation of RPA is a bit challenging. Here we mention a brief account of challenges related to RPA implementation along with their solutions.

Implementation Challenges for RPA in Manufacturing

While RPA plays a vital role in increasing agility, its implementation poses some challenges. One hurdle is identifying the right processes for automation. It is fair to mention that every task is not a good fit for automation and focusing on complex or exception-driven ones can lead to failure. Secondly, integration of RPA with existing systems can be tricky, as bots need seamless access to data across platforms. Finally, the manufacturing industry may face organizational resistance. Change can be uncomfortable for some employees as they fear job displacement.

Strategic planning and proper execution with training are essential to overcome these challenges. A renowned RPA solution developer can conduct a thorough workflow analysis before initiating the bot development. Along with this, manufacturers need to invest in data governance and infrastructure to make the most of RPA solutions. Finally, proactive communication and proper training can address the employee’s concerns to reduce organizational resistance significantly.

Future Trends in RPA for Manufacturing

As per the recent survey, 43% of manufacturers have started using RPA and another 43 percent are in the process of deploying this technology. This result indicates a bright future for RPA in the manufacturing sector. Here are some future trends we can focus on-

- Integration with AI and ML

This integration will make software bots more intelligent and capable of performing complex tasks like optimizing production schedules.

- Cognitive RPA

It will give bots the ability to understand unstructured data and make proper decisions independently based on their analysis.

- Hyperautomation

It will combine RPA technology with other futuristic technologies like IoT and digital twins to enable end-to-end process automation in the industry.

Apart from these trends, we will witness the democratization of RPA which will make it easier for smaller manufacturers to leverage its benefits. It is fair to mention that all these trends will make RPA more powerful and prevalent than ever in the manufacturing sector.

Concluding Remarks

The revolutionary RPA technology can bring transformative changes in the manufacturing ecosystem. It can increase efficiency, accuracy, and productivity without increasing operational costs. RPA in manufacturing will have a shining future with trends like hyperautomation, AI/ML integration, and cognitive RPA.

Silver Touch Technologies Canada is your one-stop destination for robust RPA solutions. Our in-house team of experienced professionals has hands-on experience in integrating RPA into the manufacturing industry. We can help you make the most of RPA to optimize processes and gain a higher ROI. Want to know more about our RPA services? Simply drop us a line at info@silvertouch.ca and one of our expert consultants will get back to you as soon as possible!

FAQs

RPA in manufacturing is about deploying tireless software robots to handle repetitive tasks like data entry, order processing, and reports. It can free up workers for other productive tasks.

RPA can automate rule-based, time-consuming tasks like purchase orders, inventory management, vendor communication, data entry, and quality control.

While ideal for high-volume, repetitive tasks, RPA might not be suitable for complex, decision-making processes. It is better to analyze your workflows to identify the best automation opportunities.

A manufacturing company can identify repetitive tasks and choose the right RPA tool based on ease of use, industry relevance, and scalability. A reputed RPA solutions provider can develop and deploy bots for performing specific tasks and give the necessary training to workers.

UiPath and Automation Anywhere are some of the top RPA tools for manufacturing. We are an official partner for both UiPath and Automation Anywhere.